FELK Trailer Floor Repairs

FELK has earned a reputation over the past 50 years as the go-to service provider for repairs to trailer floors, and other maintenance requirements, in NSW. We put our clients’ safety first, which is why we are extremely thorough and are fully ADR compliant.

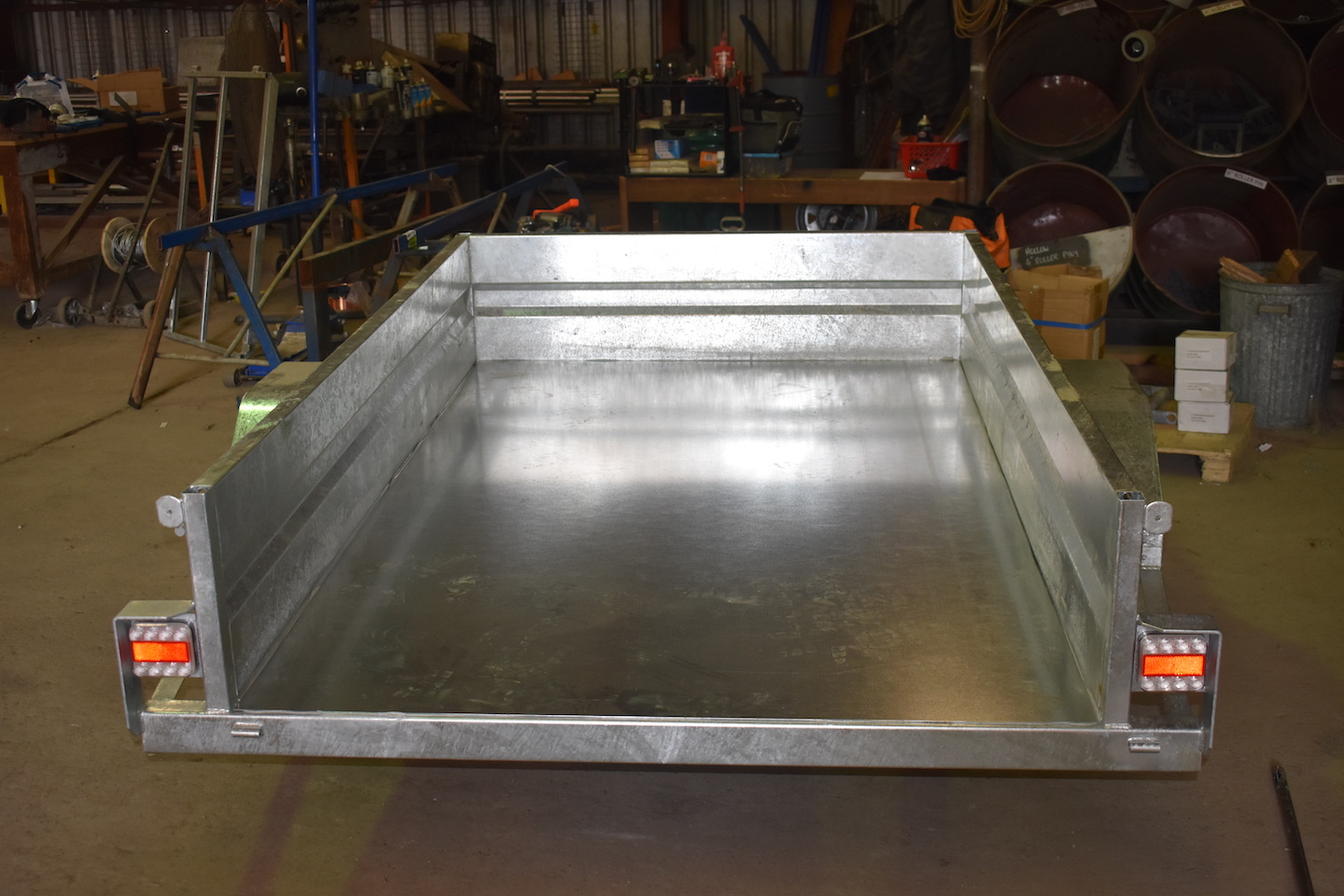

We manufacture high-quality trailers from our factory in Warners Bay. Our engineers are skilled and experienced in the repair of trailer floors from various trailer makes and models.

Why Trailer Floors Need to be Replaced

A very common reason is rust. This is especially the case for trailers that are made using non-galvanised steel.

Overloading can also lead to a trailer floor being compromised. We recommend adhering to the recommended loads of trailers to prevent damage.

Our galvanised and durable FELK trailers do not require the level of repairs we see with other brands, assuming our maintenance recommendations are adhered to. For example, we’ve worked on trailer floor replacements caused by soil and wet grass being left on a trailer floor for two years. These materials trigger a chemical reaction that inevitably leads to rust damage of the trailer floor.

Even high-quality galvanised trailers like FELK trailers, will become damaged under these circumstances. Although they will tolerate water in them for a period without any rusting, it’s worth noting Felks recommend the trailer is washed down and tilted to remove excess water and materials & then tilted when being stored to allow any water to drain out the back.

Assessment and replacement

Our engineering team will assess damaged trailer floors, looking thoroughly at the integrity of cross beams underneath. In some brands, these cross beams can become rusted and damaged in which case a repair may not be possible.

With other brands, removing and replacing a trailer floor may be impossible or extremely difficult, so when there is extensive damage, the trailer has to be scrapped altogether. After a thorough inspection, our engineers will advise you on the options moving forward, with safety at the forefront of our priorities.

When removing the trailer floor, we ensure that no damage is done to the galvanised steel structure. We carefully prepare the surface again, before reinstalling the new trailer floor.

FELK Trailer Floors are Easily Replaceable

In the rare cases that we are repairing our own floors, this is quite a straight forward job.

The difference with FELK trailers is that our trailers’ unique design means we can remove a rusted trailer floor and replace it with little fuss. This is because, instead of welding trailer floors to the crossbar, we use a robust and extremely durable product to glue the floor down. This product is the same used by Truck and bus manufacturers.

This is just another way that FELK trailers offer customers a product that promises a longer life span, compared to other manufacturers.

Timeframes to Perform Repairs

Any downtime without your trailer for leisure or work is inconvenient. Our engineers are skilled and efficient, and we typically only need one week in the FELK workshop to replace a trailer floor.

Using the best quality galvabond, you can rest assured that your new trailer floor will offer you the durability, and strength you need to get the job done. Please allow a few days after your trailer is scheduled to be fitted with a new floor, in order to allow the glue to cure.

If you have any queries about trailer floor replacements or wish to book your trailer into our workshop, please contact us.