FELK Actuators

NSW Roads and Maritime Services requires any trailer over 2 tonne GVM (the weight of the trailer plus load) to have a breakaway system installed. This can be on either Electric or Hydraulic drum brake trailers or Hydraulic Disc on Boat Trailers. An in-cab controller is also required by RMS to be fitted to the tow vehicle, with a battery monitor to operate the braking systems.

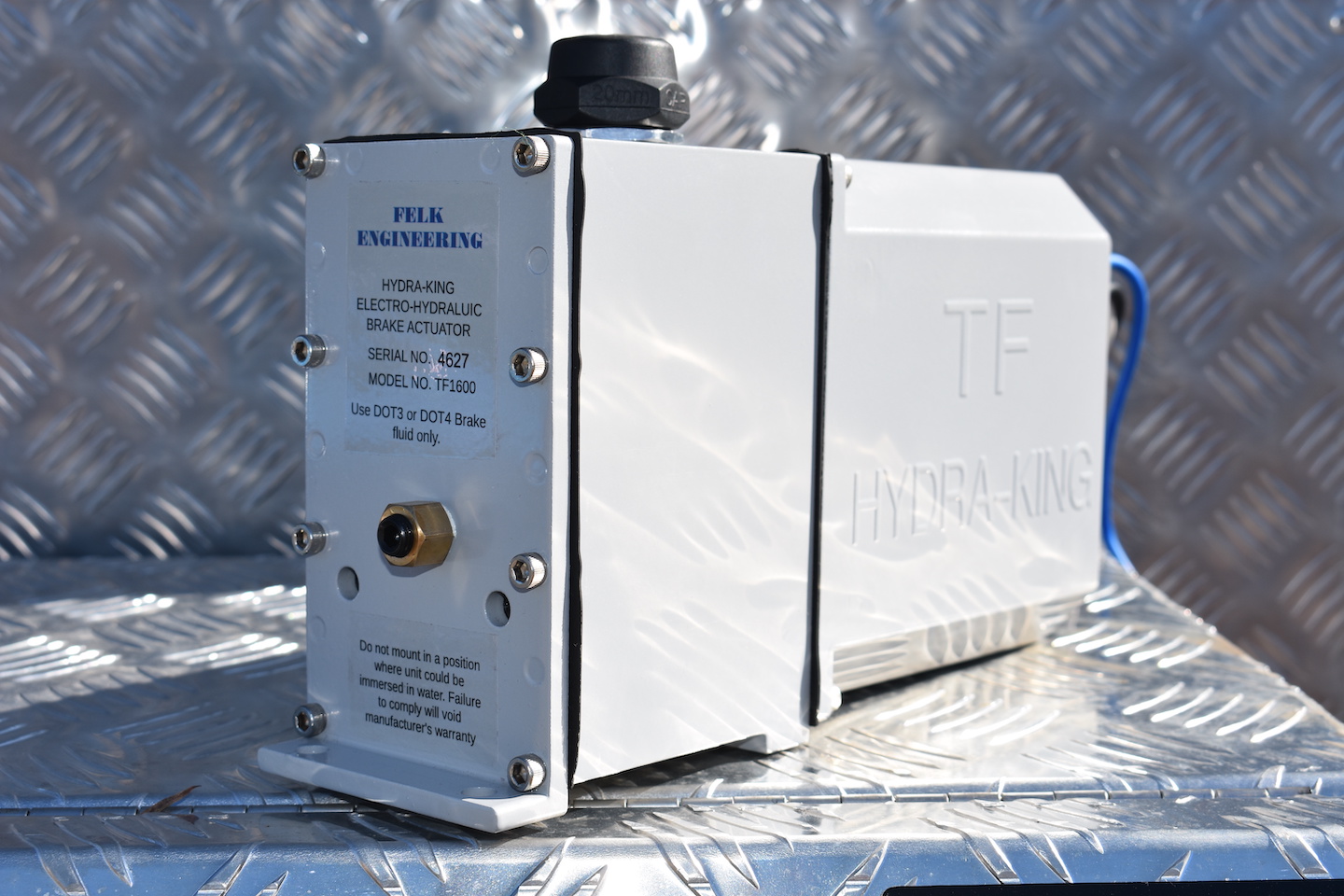

The TF Electro-Hydraulic Actuator, designed and developed by Ted Felk, is made in Australia by FELK Engineering using FELK designed and imported parts.

The TF Electro-Hydraulic Actuator, designed and developed by Ted Felk, is made in Australia by FELK Engineering using FELK designed and imported parts.

The unit is rated at 1600 psi and 12 volts.

The TF design features separate enclosures for the oil reservoir and the motor/circuit board. In the event there is a need to repair/replace the solenoid or circuit board, access to the oil reservoir section of the actuator is not required. By removing just 4 screws on your TF actuator, the motor/circuit board and solenoid cover come off for easy access and repair.

FELK Engineering makes the actuator unit in our own factory, therefore parts are readily available.

TF actuators are a neat and compact, advanced design unit measuring only 255mmL x 84mmW x 150mmH.

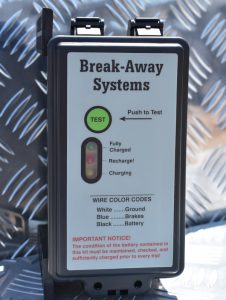

The breakaway kit includes battery box and battery, breakaway switch and charger/battery tester.

The actuator installation only takes a few minutes; all that is needed to install your TF Electro-Hydraulic Actuator on the drawbar of a trailer is a simple bracket and a U bolt.

The TF unit will work with all Proportional/Digital In-Cab Controllers:– Dexter Predator, Hayes Genesis, Endeavor, Tekonsha P3, and Redarc Tow-Pro.

A proportional controller switches to neutral mode (as does the actuator) when the trailer stops, therefore oil stops pumping and damage to the actuator is avoided.

Time based in-cab controllers are NOT ALLOWED and will void the warranty of our actuator. Time based controllers work the actuator at full power even when the brake pedal is depressed at traffic lights or in traffic jams. This will overheat or even burn out the circuit board or the motor of the actuator.

Actuator Service & Warranty Manual

Please download the TF1600 Service & Warranty Manual.

Actuator Wiring Diagram

Please download the TF1600 Schematic Wiring Diagram PDF.

Actuator FAQ

-

What is an Electro-Hydraulic Brake Actuator?

An actuator is a braking system designed to operate with hydraulic brakes. It will work with drum or disc brakes, most commonly in marine type disc brakes applications, such as boat trailers that are rated over 2 tonnes GVM.

Actuators can be used with other types of trailers if preferred over the standard electric drum type braking systems.

Actuators apply pressure through the hydraulic lines and fittings to the brakes of the trailer. This is operated by the proportional in-cab control system.

A typical actuator consists of a brake fluid reservoir, pump, motor, and a variable solenoid control valve. -

Why should I choose a Felk actuator?

- Our models are manufactured in Australia at our Warners Bay factory using high-quality components.

- We have stock and parts readily available.

- We are only a phone call away to help you with any technical questions or future servicing.

- Any repairs or servicing are usually completed within a matter of days, not weeks.

- Our pricing is very reasonable compared with the market – and our product is exceptional quality.

- Our focus is to provide the Australian market with a quality product.

-

What does the breakaway kit do?

In the event that the trailer becomes disconnected from the tow vehicle, the breakaway kit will pull the pin out from an electrical switch which is connected to the tow vehicle by a wire.

Once activated the battery box will supply charge directly to the actuator therefore engaging the braking system. This is an emergency backup system.

-

Why do you sell a version without a breakaway kit?

We sell actuators without a breakaway kit for trailers that are under 2-tonne GVM, to customers that still prefer the actuator system over the conventional mechanical override systems.

-

How many volts is a FELK actuator?

Our actuators run off 12 Volts.

Occasionally we get requests for 24 Volt actuators, however, we do not sell a 24 Volt version or a converter. In the event you have 24 Volts, you will need a converter and an auto electrician will be able to help you.

-

How much is postage throughout Australia?

Actuator only: $35 Express Post

For actuators and breakaway kit: $55 Express Post

Tracking numbers are provided for your convenience.

-

How long is the warranty for the actuator?

2 years. The unit must be installed by a professional auto electrician or electrician.

If our clients do experience a warranty issue we handle this promptly and to the highest standard. We have a full service and testing facility for actuators on-site at Warners Bay.

-

What happens if I have a warranty problem?

The first step would be to simply call us. We’ll put you onto our technical team and they will try and troubleshoot the problem over the phone.

If we’re unable to help you over the phone, we’ll request that you post the unit back to us. Our engineers will test the unit, diagnose the problem, and promptly return the repaired unit. In this event, we cover the cost of the postage back to the customer.

If the problem is not a valid warranty issue or the warranty period has expired, we will diagnose the problem and then contact you with the cost to repair. You will then have the opportunity to advise which way you would like to proceed. The customer will incur the costs of repair plus postage.

-

How do I know if I should repair or replace my actuator with a new unit?

Actuators are comprised of many components, such as a housing, pump, circuit board, motor, solenoid, valves, O-rings, etc. If an actuator isn’t functioning properly, the parts can be quite difficult and expensive to find, depending on the manufacturer of the actuator.

The best course of action is to contact us so we can bench test the actuator and identify what parts may be required. FELK can repair and replace non-Felk Actuators too.

At FELK you are dealing with the manufacturer, which gives us the ability to offer brand new actuators for a very reasonable price (listed above on the page).

Approximately half of the people who call us for advice end up purchasing a new one, basically choosing the ease of installing a reasonably-priced brand new and warranted actuator, rather than paying half as much or more for parts and repairs. That’s assuming we can actually source those parts in for non-Felk actuators.

-

What actuator maintenance tips would you recommend for people at home?

We recommend regularly topping up the brake fluid, and changing it completely once a year. The system should also be tested to make sure everything’s operating properly. Nothing too technical – just taking the trailer for a run around the block to make sure you can feel the brakes working. The most important thing to remember is that actuators are not submersible. They are water-resistant but not impenetrable to water, so if it is submerged, particularly in saltwater, the warranty will be void.

Submersion in salt water will corrode the working parts inside the housing.

-

What if someone is washing their trailer and they accidentally hit it with the hose?

That’s fine. Water splashes from a hose, rain & extreme weather won’t do any harm.

-

What kind of brake fluid do you recommend?

DOT 4.

-

Does your actuator work on all trailer models and brake types?

Yes, as long as it has hydraulic lines and fittings. (FELK Engineering is able to install a hydraulic fit out if a trailer requires it).

Actuator Returns

Felk Engineering supports our clients with actuator returns where appropriate.

Actuator Returns Form

Upon receiving the actuator, Felk Engineering will assess and contact you to confirm whether it is a quote for repair or an approved warranty claim. * Conditions apply